Design has a critical and direct impact on product lifestyle costs, harnessing component optimization and manufacturing technology during production. Choosing the right partner for this stage will guarantee that your product is optimized for

manufacturing processes, mass production and after-market service. It is our effort to create a viable design enabling your product to be assembled quickly, in a cost-effective way, with exceptional quality.

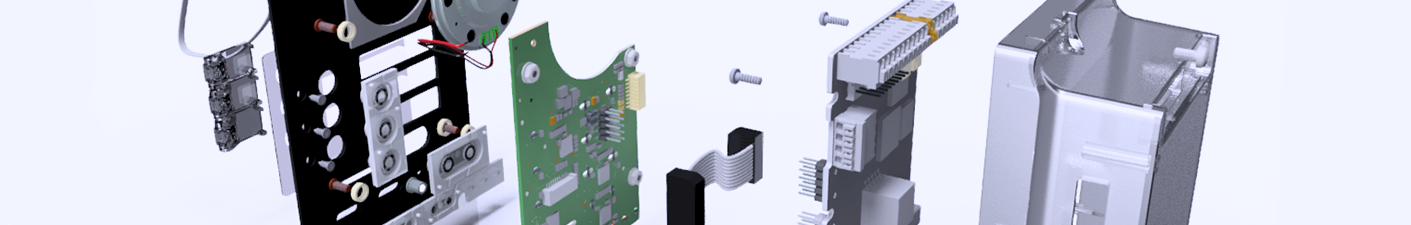

Design has a critical and direct impact on product lifestyle costs, harnessing component optimization and manufacturing technology during production. Choosing the right partner for this stage will guarantee that your product is optimized for manufacturing processes, mass production and after-market service. It is our effort to create a viable design enabling your product to be assembled quickly, in a cost-effective way, with exceptional quality.

Design for Excellence

- Design for Manufacturing

- Design for Testability

- Design for Assembly

- Design for Costs

Advantages

- Improve the product quality and user experience

- Enhance manufacturing process

- Reduce product lifecycle costs

- Speed up time to market

- Increase customer satisfaction