If you think

Fideltronik

think timelessness,

quality and consistency

Design & Development

Power

Conversion

We are specialized in SMPS blocks for industrial, consumer and medical purposes, including mains-supplied devices.

Our deep experience covers isolated and non-isolated power blocks converting power from 1 W up to 30 kW:

- Power Supply Units

- LED drivers (dimmable and fix output), including control interfaces

- LED lighting, including UV sanitization

- Welders

- Inverters (software-controlled sinus output), including emergency purposes

- Battery chargers with digital control charging algorithms and battery condition detecting

- Home appliances built-in PSU units

- Battery Management Systems (BMS)

Our development process focuses on:

- Safety construction

- EMC compatibility, including high surge immunity, active PFC for harmonics emission reduction

- Compact size

- IP and IK protection levels

- Active and passive cooling systems

- efficiency and extra-low standby power losses for eco-design regulations,

- Robustness for vibration and moisture

Our products supply lighting of most known

sport areas and airports worldwide

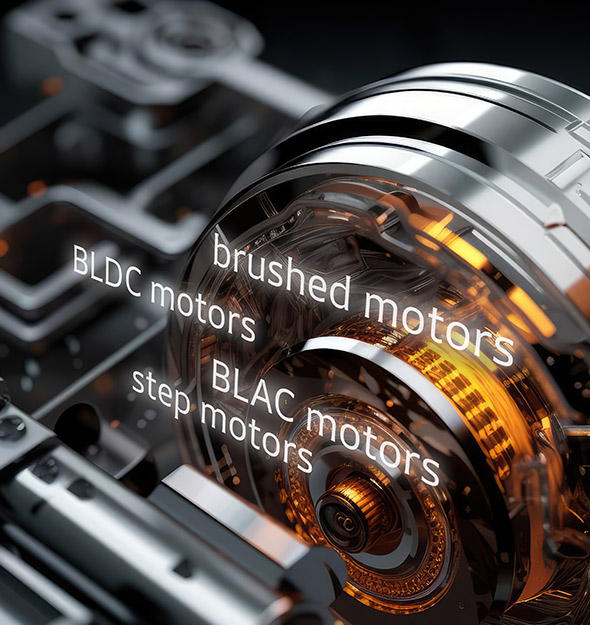

Motor

Control

We offer development of power blocks and digital microcontroller-based control for driving:

- Brushed motors with smooth control via customized PWM algorithms

- BLDC motors

- BLAC motors

- Step motors

- Sensor-less transmission systems based on lead screw

Our designs control motors in products with touchless sanitization functionality

IoT

Modules

Our IoT solutions for new products or for updating existing products include:

- Data to cloud connection

- Control device from the cloud for remotely settings modification

- GPS tracking

- Hardware functions enabling in pay-as-you-use model

We are experienced in following interconnections:

- Wired: LAN, CAN, DALI, 1-wire, RS-485, I2C, SPI, UART

- Wireless: GSM, LTE, Wi-Fi, Bluetooth BT/BLE, ZigBee, LoRa,

CAT-M, NB1, NFC, MQTT

We are specialized in battery- and cable-powered devices.

Our development process focuses on:

- Privacy and data safety

- Product energy consumption optimization

- EMC compatibility for RED directive

Our IoT modules communicate products with the Cloud for full monitoring

Industrial

Sensing

Sensing of machines and devices operating conditions and parameters is crucial for industry processes supervising:

- Monitor device parameters

- Work conditions monitoring, remote diagnostics & events detecting

- Device safety monitoring via accelerometer data analysis

- Environmental conditions recording (precise thermal sensors,

humidity sensors, vibration sensors based

on digital accelerometer)

Our experience covers also industrial input cards:

- High-precession analogue-digital inputs

- Thermocouple sensors

- PIR movement detection

- Light detection

- Audio signal digital processing

Our sensors monitor production environment of Smart Factories

Medical

Projects

We offer design of devices for healthcare market products following ISO 13485 medical devices standard:

- Sensors for use by healthcare professionals

- Equipment for hospitals

- Control interfaces, including mechanical design

- Touchless user interfaces

- Devices firmware that complies with medical & security SSL

to keep sensitive information safe - UVC light sanitization

Our HW & SW designs support hospitals on information security level

R&D in numbers:

Engineers

Engineers

Software

Engineers

& Validation

Specialists

Engineers

& Technicians

Prototyping

Rapid prototyping

allows quick yet

thoughtful decision

Quick response is what distinguishes us on the EMS market. And that is what our customers are looking for specificly when evaluating their ideas in R&D phase. We guarantee not only

3-week delivery time for the high-complexity PCB, but – as a part of the well-reputable EMS company – we can support our customers with the wide range of additional services:

- Material and PCB acquiring mainly basing on Fideltronik

inventory and catalogue suppliers (components delivery time

up to 5 working days, PCBs delivery time 3 -15 working days) - SMT reflow soldering (chip components from 0201,

BGA pitch 0.35mm, Pin-In-Paste) - THT wave, selective or manual soldering

(axial, radial, manual assembly, PressFit) - Testing (standard AIO, on demand: Flying probe,

ICT, FCT, X-ray, visual inspection, manual test) - Conformal coating, siliconing, potting

- Final (mechanical) assembly

- Protypes build report

- Packing and shipment

- Rework process (to help our clients with product

modification if needed).

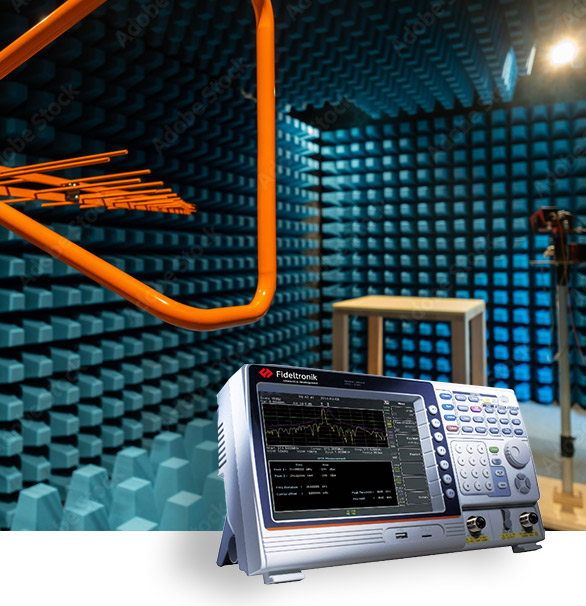

Quality under control

Validation testing

is essencial to meet

regulatory requirement

It also helps to leverage performance of the final product and reduce the risk of costly non-compliance on the final design stage.

Validation test are planned and executed by qualified engineers in our own laboratory and include:

- Electromagnetic compatibility (EMC) tests

- Environments tests: Thermal, Humidity and Aging

- Optical tests

- Performance and endurance

- Functional tests

- Safety and control tests

- Certification process lead, including DFMEA coordination

- MTBF calculation replacement

- DFT, DFM, DFR verification & support

We rely on our domain knowledge and expertise in delivering the best service quality to our clients, according to their needs and expectations.

Drawing from our extensive expertise, we can lead our clients through whole certification process for global markets, e.g., CE / UL / FCC.

We are here to support your engineers on each and every stage of the preparations.

About

Fideltronik RnD is present on the global market since 1996 as a part of Fideltronik Poland – one of the largest EMS providers in Europe. During 27 years of close cooperation with our clients around the globe we successfully delivered hundreds of devices to various industries.

We care about our customers’ success and effectively support their product competitiveness by innovative design, costs optimisation and speeding up time-to-market. It is achievable thanks to close cooperation with Fideltronik EMS, where Artificial Intelligence and Industrial Analytics create an innovative ecosystem for highly demanding projects.

Whether you are looking to launch a new product or modernize your existing device, our Fideltronik R&D team can help you to explore new opportunities and identify potential areas of business growth. We offer product design & development, validation & certification, industrialization & production sustaining supported by rapid prototyping and process verification. You can rely on our strong expertise in:

Reliable partner

for materializing

your ideas