Opting for a cheaper price at the expense of quality is a risky strategy in electronics design. EMS companies must prioritize transparency with clients, informing them of potential drawbacks and finding the optimal solution.

In industries where quality is everything, a low price can be a threat / liability rather than a bargain. Clients who prioritize low costs inadvertently expose themselves to long-term risks they may not fully realize. If this is the case, it’s in their best interest to consider finding the right balance between expenses and desired outcomes under expert guidance.

How to approach a project focused on the lowest pricing?

The client is always right. Except when they jeopardize their own business by explicitly wrong decisions, and they can be helped by professional advice.

Obviously, the role of a Design House (RnD) or Original Design Manufacturer (ODM) company is not to provide unwarranted mentoring. Still, an experienced contractor is obliged to cater to the client’s needs with the best intentions possible – even if this entails suggesting significant revisions to the original idea or project.

A common situation where such an intervention is suitable or outright required is when a client emphasizes the cheapest solutions. While keeping costs down is always a desirable goal in electronics design, focusing solely on the lowest pricing can lead to a cascade of problems down the line.

Hence, it’s imperative that a contractor, in the most tactful manner, highlights the trade-offs related to such an approach.

The downsides of the budget-driven design

Every seasoned electronics design expert is familiar with the drawbacks of a cost-centric approach. They include:

– hidden costs and compromised performance: the cheapest components often have higher failure rates and inferior performance specs impacting efficiency, decreasing MTBF and, in the end, negatively affecting the reliability of the final product,

– limited testing: keeping the budget tight may limit the scope of analyses and simulations, impacting reliability (DFMEA) and production costs (DFM/T/A), increasing the number of no-fault-found complaints and servicing costs (DFSS/sensitivity), and lowering the product’s perceived quality,

– compatibility issues: super-cheap components might not integrate seamlessly with other parts of the design, decreasing the product’s parameters and causing , leading to compatibility issues over time, which may require withdrawing the product from the market additional workarounds,

– safety concerns: using low-quality components and simplified solutions might mean cutting corners on safety features and putting users at risk, resulting in product recalls, damaged brand reputation, and even lawsuits,

– maintenance headaches: designs built with cheap components might require more frequent maintenance or repairs, increasing overall costs in the long run.

The list goes on. Fortunately, it can be reduced to zero by proper guidance and putting the project in the right perspective.

Let’s keep things real: full transparency vs overpromising

It’s understandable that clients aim for the best cost-to-value ratio. However, they’re not always aware of the limitations and challenges involved in bringing their ideas into reality.

Many companies expect premium features at standard or low prices. These goals are obviously in contradiction . Premium functionality typically requires high-quality components, complex design features, and potentially advanced manufacturing processes.

An eager contractor trying to appease a client may try to bridge this gap by downplaying potential risks, overpromising on performance, suggesting untested solutions, and failing to convey clear information. Such compromises are dangerous and tend to backfire in the long run.

The number one rule for avoiding disappointments and pitfalls in the electronics design process is to maintain clear communication and full transparency with the client right from the beginning.

Feasibility check

EMS and ODM contractors bring a wealth of experience and knowledge to the table. They can analyze the client’s original ideas and assumptions about functionality, components, and manufacturing processes, providing essential insights and recommendations.

Such a consultation may be an unpleasant reality check for the client. In fact, it protects them from a much bigger disenchantment related to the previously described drawbacks.

A standard measure to prevent mistakes and misunderstandings later in the process is a feasibility study (proof of concept), which assesses the project’s practicality. Such an analysis helps determine if the client’s desired product is achievable within the specified budget.

If not, it explores alternative solutions that best meet their needs. A reasonable approach is to provide a client with a choice of options adjusted for different budget limitations, for example, low-cost, medium-cost, and premium ones.

Functionality and cost optimization based on the client’s feedback

At Fideltronik, the process is fairly straightforward and cost-efficient. Based on our over 20 years of experience in manufacturing energy processing systems, we create functional mock-ups with functional blocks verified in other projects.

We’re able to design the initial model of the device at a relatively low cost to demonstrate how we can solve the problems in question to achieve the client’s goals.

The next step is to collect the client’s feedback and optimize the prototype both feature-wise and cost-wise. The client should be aware of which factors have the biggest impact on the project’s price and production deployment costs.

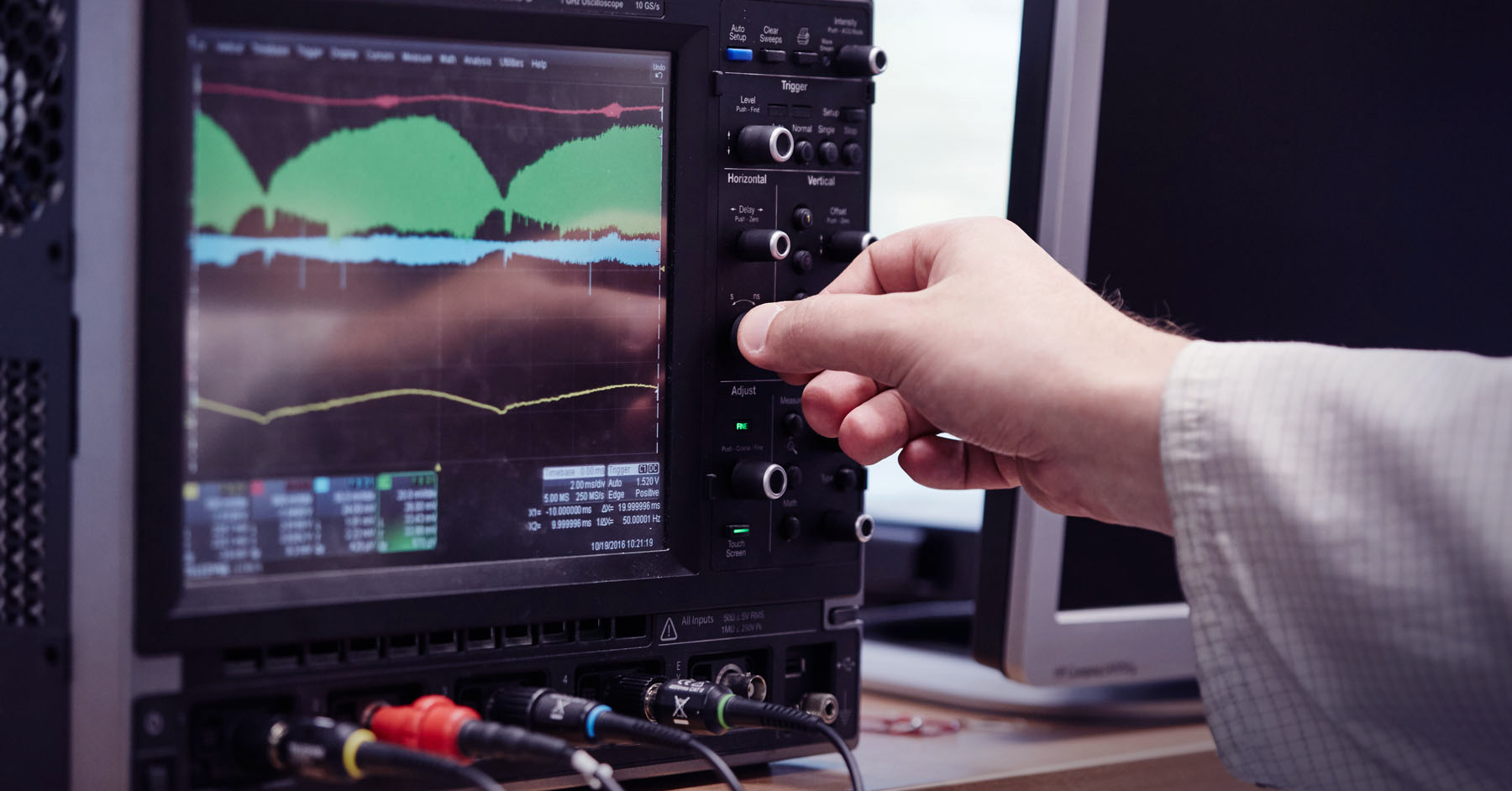

Strategies to mitigate expenses without compromising quality should also be discussed. Keeping things transparent allows us to minimize the risk of unexpected results during further project stages focused on EMC and thermal tests.

Prioritizing empathy

Focusing on the client’s needs and maintaining clear communication throughout the process is paramount for the project’s success. Approaching clients with empathy helps us better understand their goals, needs, and constraints, contributing to smoother and more efficient cooperation. It also facilitates exploring creative solutions that may overcome the initial limitations.