support humans in monotonous and routine tasks

m: +48 33 874 98 00

e-mail: office@fideltronik.com

m: +48 33 874 98 00

e-mail: office@fideltronik.com

Synergy of advanced technology, information

and communication to improve manufacturing efficiency

Sophisticated technology that can collect, analyze and utilize data lies at the heart of our Smart Factory. The main goal is to optimize processes across the manufacturing ecosystem, improving efficiency, flexibility and safety. The idea is not only to bring market advantage for ourselves but to effectively support our clients’ competitiveness.

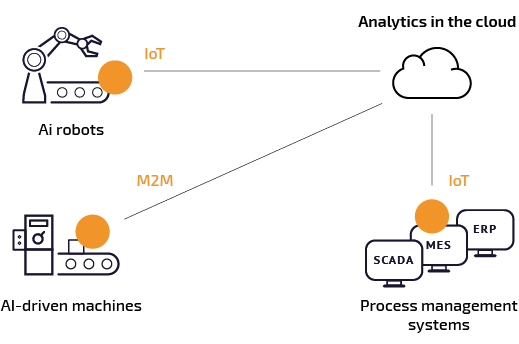

There are three factors making our manufacturing processes smarter and self-optimized:

AI-driven machines and processes – enable highly advanced automation and self-optimization. These result in more effective production, planning, management and supply chain logistic.

Dedicated sensors combined with IoT – connectivity that allows for a crucial data collection in the Cloud.

AI-driven Industrial Analytics – provides meaningful reports, statistics and alerts supporting predictive maintenance to secure seamless operations in the factory.

Read more >>

There are three factors making our manufacturing processes smarter and self-optimized:

AI-driven machines and processes – enable highly advanced automation and self-optimization. These result in more effective production, planning, management and supply chain logistic.

Dedicated sensors combined with IoT – connectivity that allows for a crucial data collection in the Cloud.

AI-driven Industrial Analytics – provides meaningful reports, statistics and alerts supporting predictive maintenance to secure seamless operations in the factory.

Our factory is the first place where we implement our reliable smart solutions. Drawing from synergy of experience in the areas of Industrial Automation, IoM and AI, we build machines and systems that fully correspond to INDUSTRY 4.0 principles. Manufacturing processes are automated and self-optimized based on AI algorithms and machine learning.

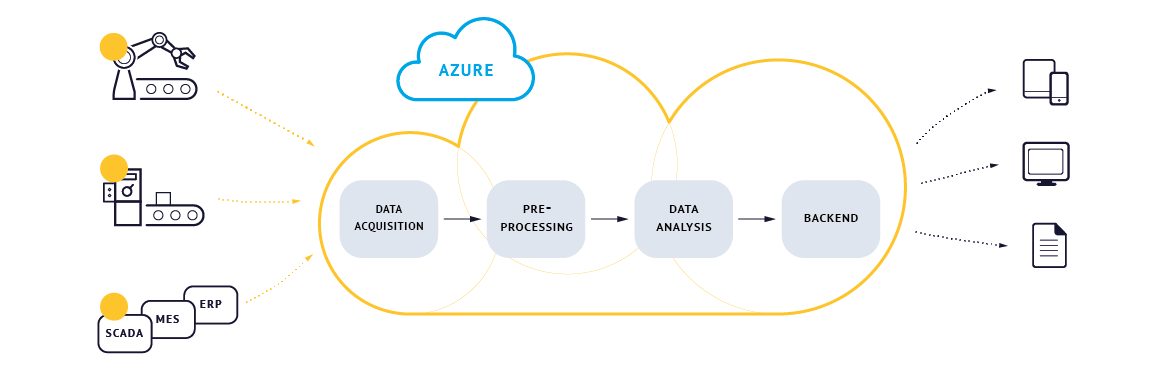

Data generated by the machines or sensors is sent to the MS Azure Cloud, where industrial analytics generates statistics

for further process improvement. Such an approach lets us minimize machinery failures, secure process continuity as well as improve production quality. As a result, we can offer our customers a more flexible and efficient production process through resource optimization, real-time tracking and process automation. Our customers benefit from cost and time-to-market reduction gaining considerable market advantage over competitors.

Our factory is the first place where we implement our reliable smart solutions. Drawing from synergy of experience in the areas of Industrial Automation, IoM and AI, we build machines and systems that fully correspond to INDUSTRY 4.0 principles. Manufacturing processes are automated and self-optimized based on AI algorithms and machine learning.

Data generated by the machines or sensors is sent to the MS Azure Cloud, where industrial analytics generates statistics for further process improvement. Such an approach lets us minimize machinery failures, secure process continuity as well as improve production quality. As a result, we can offer our customers a more flexible and efficient production process through resource optimization, real-time tracking and process automation. Our customers benefit from cost and time-to-market reduction gaining considerable market advantage over competitors.

Read more >>

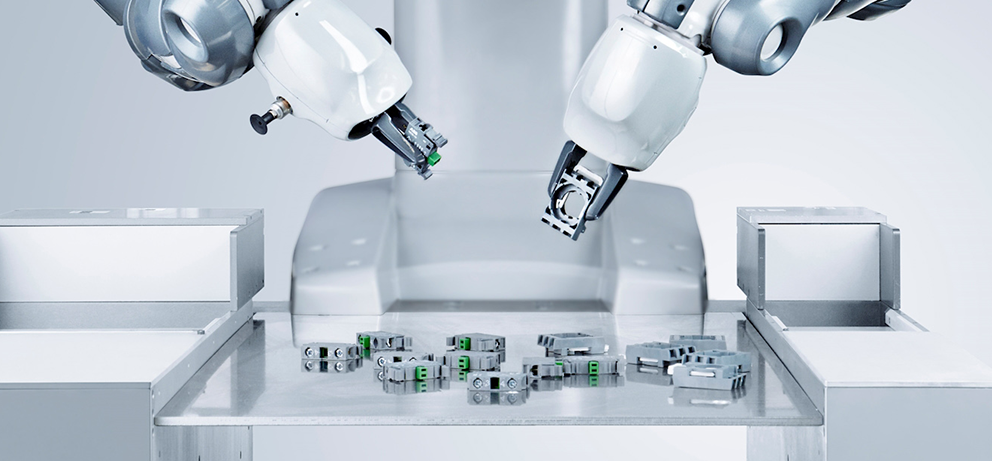

Smart Component Assembly robots incorporate AI computing and machine learning to provide intelligent and operatorless component placement to:

Smart Optical Inspection boosts the PCBA inspection process to improve quality, increase efficiency, and reduce setup as well as operational costs. It allows AI power to:

Industrial Analytics Solution combines statistical and machine learning algorithms to reshape manufacturing processes and infrastructure maintenance, ensuring stability and continuity as well as improving efficiency and reducing operational costs. The analysis is performed by AI-powered software to generate reports, statistics, alerts and predictions for process and infrastructure improvements. Data for analysis is collected and stored in the MS Azure Cloud to be utilized according to business needs. The solution incorporates a set of customized sensors connected by IoT to the networking infrastructure and Cloud database. As an integral part of our intelligent machines and robots, this allows them to perform ever more efficiently in the manufacturing ecosystem of our Smart Factory.

Continuous investment in technology, process automation and robotization lets us improve productivity and follow our zero-defect philosophy. Due to the high level of automation, especially of various special processes, we can guarantee optimized production costs of your product. By eliminating the unreliability of manual tasks, minimizing waste and manpower we can respond more effectively and cost-efficiently to fast-changing market and client needs. All special processes are driven by AI or qualified procedures resulting in high precision and high speed of overall production.

Smart Component Assembly robots incorporate AI computing and machine learning to provide intelligent and operatorless component placement to:

Smart Optical Inspection boosts the PCBA inspection process to improve quality, increase efficiency, and reduce setup as well as operational costs. It allows AI power to:

Industrial Analytics Solution combines statistical and machine learning algorithms to reshape manufacturing processes and infrastructure maintenance, ensuring stability and continuity as well as improving efficiency and reducing operational costs. The analysis is performed by AI-powered software to generate reports, statistics, alerts and predictions for process and infrastructure improvements.

Data for analysis is collected and stored in the MS Azure Cloud to be utilized according to business needs. The solution incorporates a set of customized sensors connected by IoT to the networking infrastructure and Cloud database. As an integral part of our intelligent machines and robots, this allows them to perform ever more efficiently in the manufacturing ecosystem of our Smart Factory.

Industrial Analytics Solution combines statistical and machine learning algorithms to reshape manufacturing processes and infrastructure maintenance, ensuring stability and continuity as well as improving efficiency and reducing operational costs. The analysis is performed by AI-powered software to generate reports, statistics, alerts and predictions for process and infrastructure improvements. Data for analysis is collected and stored in the MS Azure Cloud to be utilized according to business needs. The solution incorporates a set of customized sensors connected by IoT to the networking infrastructure and Cloud database. As an integral part of our intelligent machines and robots, this allows them to perform ever more efficiently in the manufacturing ecosystem of our Smart Factory.

Continuous investment in technology, process automation and robotization lets us improve productivity and follow our zero-defect philosophy. Due to the high level of automation, especially of various special processes, we can guarantee optimized production costs of your product.

By eliminating the unreliability of manual tasks, minimizing waste and manpower we can respond more effectively and cost-efficiently to fast-changing market and client needs. All special processes are driven by AI or qualified procedures resulting in high precision and high speed of overall production.

Continuous investment in technology, process automation and robotization lets us improve productivity and follow our zero-defect philosophy. Due to the high level of automation, especially of various special processes, we can guarantee optimized production costs of your product. By eliminating the unreliability of manual tasks, minimizing waste and manpower we can respond more effectively and cost-efficiently to fast-changing market and client needs. All special processes are driven by AI or qualified procedures resulting in high precision and high speed of overall production.